Iziko leMveliso

I-FR A2 ALUMINUM COMPOSITE PANEL LINE MVELISO

Ingcaciso yeMveliso

1. Izinto ezingatshiyo ze-inorganic core + izinto zetsimbi yindibaniselwano egqibeleleyo yamandla, ukuguquguquka, ukumelana nomlilo, ukumelana nomswakama, ukugquma ubushushu, ukugquma isandi kunye nokuhlobisa.

2. Ukusebenza komlilo okugqwesileyo. Kuvavanyo lokutsha, akukho mlilo we-zero, akukho halogen, akukho msi, akukho tyhefu, akukho kuthontsiza, akukho radiation, njl.njl. ibonakalise ukusebenza kwayo okugqwesileyo kokhuseleko, kwaye ineempawu zokukhuselwa kokusingqongileyo okuluhlaza.

3. Ukusebenza okugqwesileyo kokuhombisa, iimveliso ezintle kunye ezintle, ukuxhathisa ukubola, ukuxhathisa ukungcola, ukunyamezela.

4. Ukudibanisa okugqibeleleyo kwamandla kunye nokuguquguquka ngokupheleleyo kwenza ukungabikho kwamandla kwepaneli ye-aluminium composite. Ingenziwa nge-hyperbolic shape, kulula ukuyifaka kunye nokugcina.

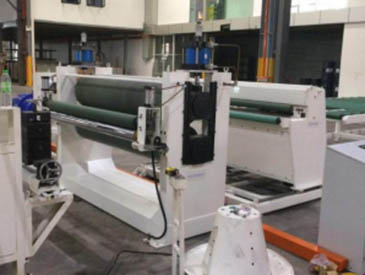

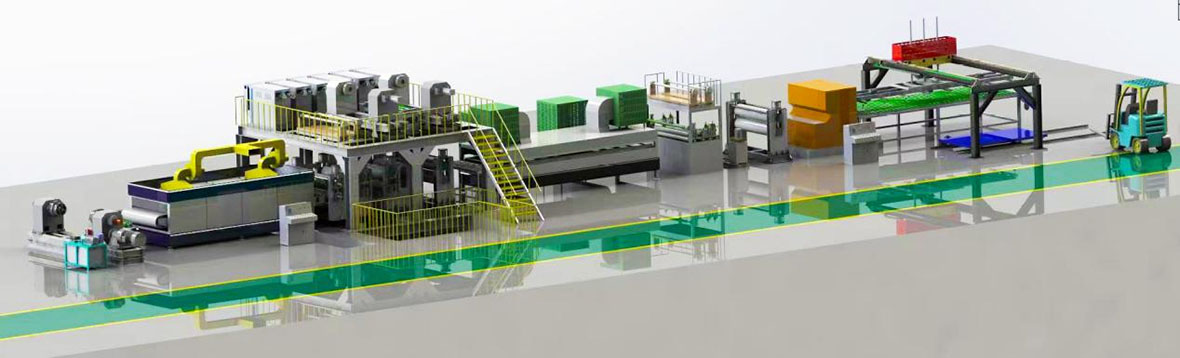

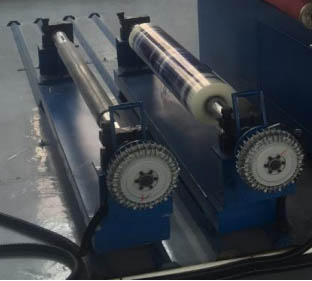

Umgaqo weMveliso

I-coiled A2 core material ikhutshwa nge-unwinder, kwaye ke into engundoqo ifudunyezwa kwiqondo lokushisa eliphezulu kwi-oven ukuthambisa i-coil engundoqo. Ngeli xesha, ikhoyili engundoqo ineplastiki. Emva kokuba izinto ezingundoqo zidlule kwi-oven, i-aluminium ephezulu kunye nesezantsi Ulusu lukhutshwa ngumatshini we-aluminium wokuvula ikhoyili, ifilimu encamathelayo igqithiswa kwi-roller yangaphambili, kwaye ifilimu encamathelayo incanyathiselwe kulusu lwe-aluminium, emva koko izikhumba ze-aluminium eziphezulu kunye nezisezantsi zidlula kwiyunithi yokudibanisa ukwenza ulusu lwe-aluminium kunye ne-core . Ubushushu bomatshini bunokumiselwa ngokwahlukileyo. Emva kokudlula kumaqela amaninzi eeyunithi zekhompawundi, emva kobushushu obuphezulu be-lamination kunye ne-extrusion, iphaneli ifakwe kwaye yenziwe, kwaye ipholile ngebhokisi yomoya epholileyo ngamanzi, kwaye idlule kwi-roller yokulinganisa ukuze unamathele ngokuqinileyo ifilimu yokunamathela. Ngeli xesha ibhodi ke ilungiswe. Emva kokuba ububanzi buchongiwe, ibhodi idlula kwidrum yokuqhuba kwaye ifike kumatshini wokucheba. Iyunithi yokucheba isika ubude obusisigxina ngokobude obumiselweyo. Emva kokuba ibhodi edibeneyo yenziwe, ibhodi idluliselwa kwi-pallet ngokusebenzisa i-platform yokulayisha kunye nokukhulula ngokuzenzekelayo. Ipakishwe, kwaye ekugqibeleni yapakishwa ngesandla kwaye yathunyelwa.